Your Authorized Swagelok Sales and Service Center

Swagelok Ontario is your local

Swagelok® Sales and Service Center

Read our latest blog post:

Custom Fabrication and Assembly Solutions Meet Your Design Specifications

From simple sub-assemblies to complex fabrications, Swagelok Ontario assembles all the fluid system components you require for a high quality single source solution.

eDTR: Download All of the Latest Swagelok Literature

Our eDTR (Electronic Desktop Technical Reference) software ensures you always have the latest Swagelok literature. Install today to gain access to hundreds of Swagelok catalogs, technical specifications, certifications, and resources which can help you quickly and easily find Swagelok solutions for your applications.

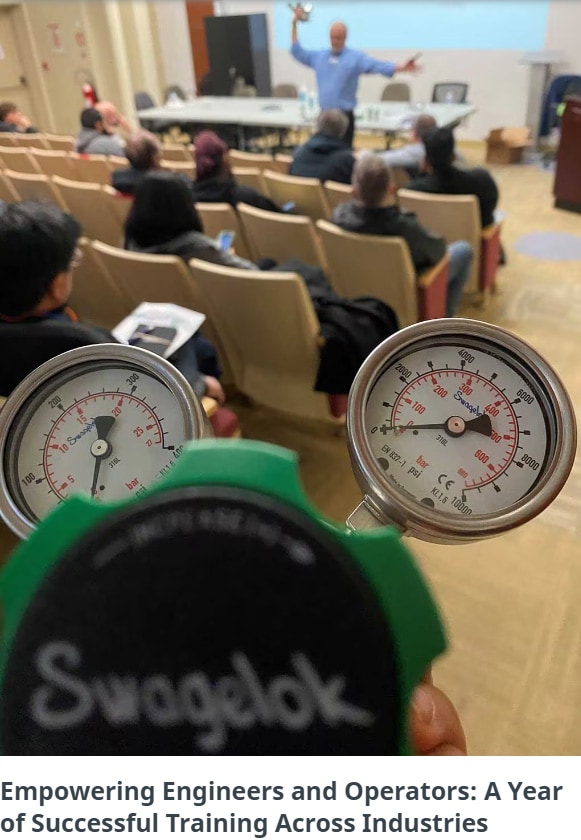

Train Your Team: Choose From Hands-On and Technical Courses

Swagelok Ontario's hands-on training seminars provide you with the practical knowledge to enhance workplace safety and improve efficiency and productivity.

Swagelok Ontario Quick Links

Featured Stories

Your Local Swagelok Sales and Service Center

Swagelok Ontario

6471 Edwards Boulevard

Mississauga, ON L5T 2V2

905.607.1825

18D Enterprise Avenue

Ottawa, ON K2G 0A6

613.226.1862

469 Campbell St.

Sarnia, ON N7T 2J1

519.336.3453